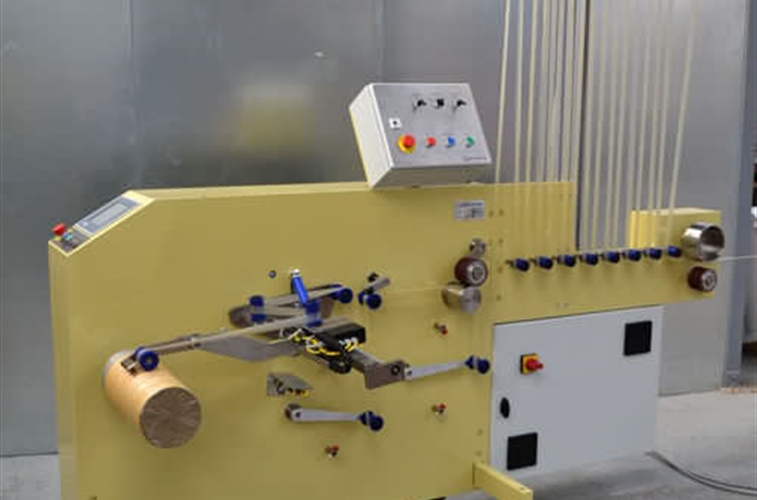

Non-Stop Spooling Machines

ALPHASPOOL spooling machines integrate with a wide range of tape and filament production lines.

Non stop operation is normally achieved with integrated accumulators providing time for the operator to load new sores or spools. For high speed lines twin spoolers with automatic cut off can be supplied so that the tape only needs to be transferred from the finished spool to the new core before restarting.

Non stop spoolers offer all the flexibility of ALPHASPOOL spoolers with configuration to suit tapes and filaments. Each spooler efficiently winds bobbins of films, tapes or filaments to level wound spools with a precise computer controlled traversing mechanism and sensitive tension control.

The cantilevered rewind shafts provide quick roll change whilst the servo control systems ensure precise spooling. All Alpha spoolers are of heavy duty construction for long life.

Standard Features

- Precise spooling tension with closed loop control

- Precise tape lay down with computerised traversing

- Integration with production line

- Multiple tension zones

- Multi roll accumulator

- Touch screen control with recipe system

- Quality engineered and manufactured in UK

Optional

- Choice of rewind shafts for cores or spools

- Quick change rewind shafts

- Guide wheels

- Guide fingers

- Filament winding

- Powered roll ejection

- Low tack roll coverings for exposed adhesives

- Multiple tension zones

- Food grade

- Clean room installation

Typical Specification

| ALPHASPOOL Non-Stop | ||

| Tape width | 0.5 to 50 mm | 0.02 to 2 inches |

| Tape thickness | 10µm to 10 mm | 0.4 mils to 0.5 inches |

| Filament diameter | 10µm to 5 mm | 3 mils to 0.2 inches |

| Unwind Roll diameter | 450 to 1000 mm | 18 to 40 inches |

| Unwind Core diameter | 76 or 152 mm | 3 or 6 inches |

| Spool diameter | To 1000 mm | To 40 inches |

| Spool width | 100 to 500 mm | 4 to 20 inches |

| Speed | 400 m/min | 1,200 ft/min |

Typical Materials

| Monofilaments (PP, PE,PES,PA) | Medical | Foam tapes |

| Technical high performance fibres | Tube | Sausage casing |

| Carbon fibre (carbon fiber) | Yarns (coated, twisted) | Brass |