Cut to Length Machines

ALPHACUT cut to length machines are supplied for cutting a wide range of materials to length.

Each machine is custom manufactured to meet the customer's demands for length, accuracy and product handling. The cutting method is selected to provide the optimum cut quality, reliability or product handling. Cut to length machines can sheet wide films with subsequent placing for laminating to the primary product or cut profiled product direct from an extruder with automatic batching into bags or boxes running on conveyorised system.

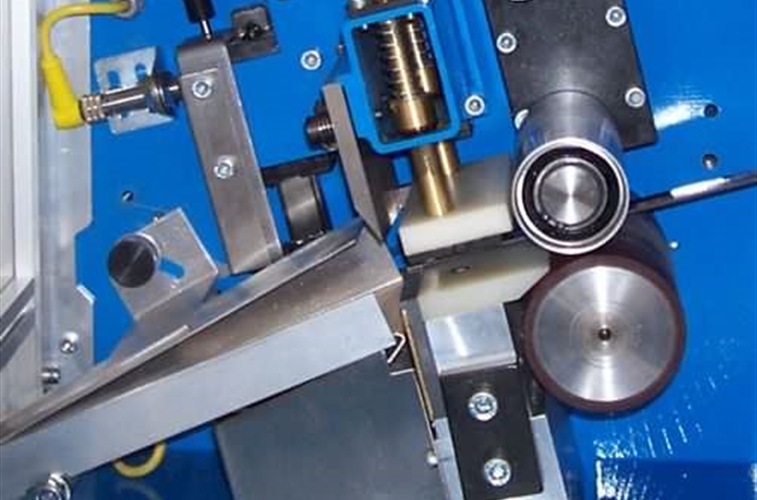

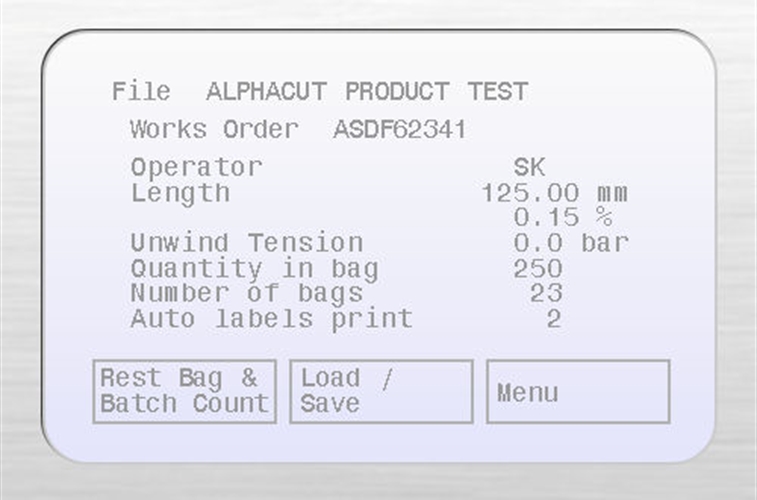

Example shown:

- Guillotine cutting for magnetic strip provides clean high speed cutting with servo strip index.

- Touch screen control provides comprehensive setting of all cutting parameters as well as production data and labelling and batch requirements.

Standard Features

- Robust cut off

- Programmable length and speed control

- Quick change cutting blades for different products

- Auto stopping at unwind core

- Touch screen control with recipe system

- Quality engineered and manufactured in UK

Optional

- Driven unwind with AC drive

- Delivery to conveyor or product bin

- Guillotine cut off

- Traversing cross cutting knife

- Edge trimming

- Round/shaped product

- In line operation with extrusion process

- Batch counting & labelling

- Slitting

- Clean room installation

- Gap mode winding (non contact)

- Peel off roll (unwind only)

Typical Specification

| ALPHACUT | ||

| Web width | 5 to 2,000 mm | 0.3 to 80 inches |

| Web thickness | 10 µm to 10mm | 0.4 mils to 0.5 inches |

| Unwind roll diameter | 450 to 1,000 mm | 18 to 40 inches |

| Cut off length | 2 to 5,000 | 0.1 to 200 inches |

| Cutting rate (maximum) | 4 pieces/second | 4 pieces/second |

Typical Materials

| Film - OPP, PET, PE, PVC | Medical | Magnetic strip |

| Non-woven | Label stock | Brass |

| Aluminium |