Duplex Slitter Rewinders

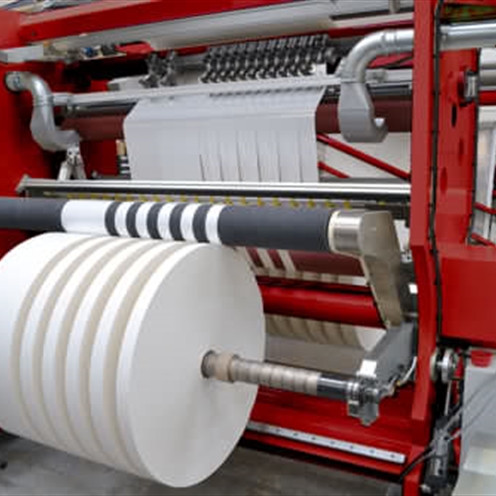

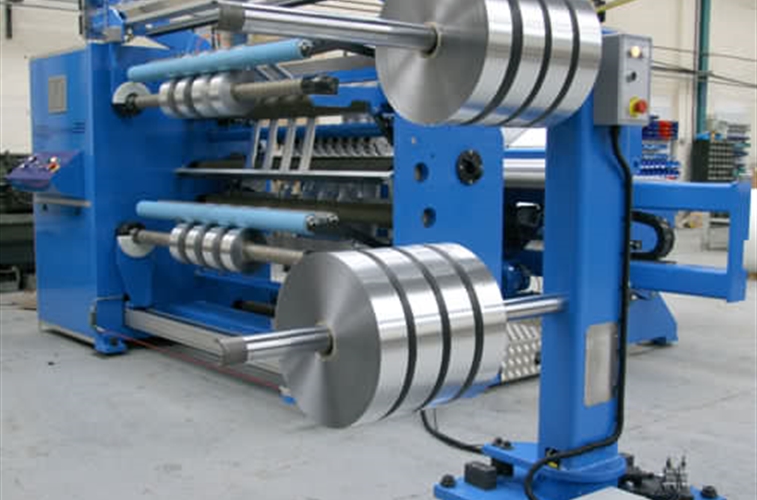

The ALPHATWIN duplex slitter rewinder is a robust shafted centre rewinder with precise tension and contact control, typically used for flexible packaging and general converting.

The cantilevered winding shafts are rigid during running yet provide for fast unloading and can easily be integrated with a variety of unloading systems. All models can be supplied with automatic knife positioning, fixed or auto setting laser core positioning and powered roll removal to improve productivity. The touch screen operator interface has simple recipe systems for multiple material types and slitting parameters.

Standard Features

- Cantilevered winding shafts with swing away support for quick roll change

- Precise tension control with spacer-less differential rewinding shafts

- PLC control with touch screen interface and comprehensive recipe and maintenance systems

- Closed loop unwind tension control

- Shear or Razor slitting

- Quality engineered and manufactured in UK

Optional

- Automatic knife setting system

- Crush slitting

- Vacuum Trim removal or Traversing Trim winders

- Powered roll stripping

- Unloading tree or trolley

- Individual layon rolls

- Laser core positioning

Typical Specification

| ALPHATWIN Duplex | ||

| Web width | 800 to 2,000 mm | 40 to 80 inches |

| Rewind diameter | 600 or 800 mm | 24 or 32 inches |

| Minimum rewind width | 50 mm | 2 inches |

| Rewind core diameter | 76 mm | 3 inches |

| Unwind diameter | To 1,800 mm | 70 inches |

| Material thickness | 10 to 500 µm | 0.4 to 20 mils |

| Line speed (maximum) | 600 m/min | 2,000 ft/min |

| Operator interface | 10" colour touch screen | |