Pneumatic Trim Winders

ALPHATRIM P winders have pneumatic powered traverse movement with a simple web path for quick threading.

ALPHATRIM P winders have pneumatic powered traverse movement with a simple web path for quick threading. The traverse rate can be adjusted by the operator and automatically switches off when the line stops.

Each trim winder is driven by its own variable speed motor running under closed loop tension control from a precision pneumatic dancer.

Alternatively, where space is at a premium, the winder motor can be operated under direct torque control. Full sized rolls can be unloaded quickly and the winder restarted. ALPHATRIM winders are fitted with a remote air inflation system on winding shafts for paper cores or a quick release mechanism on coreless shafts.

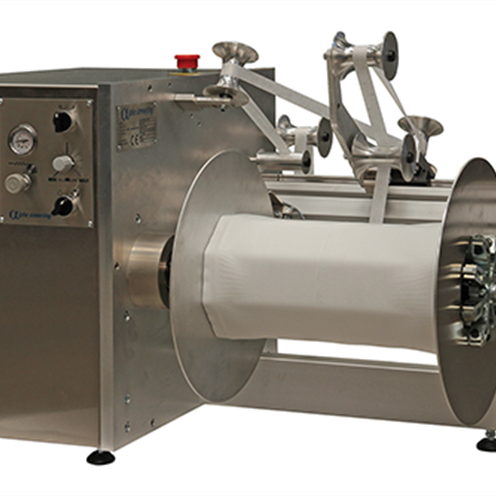

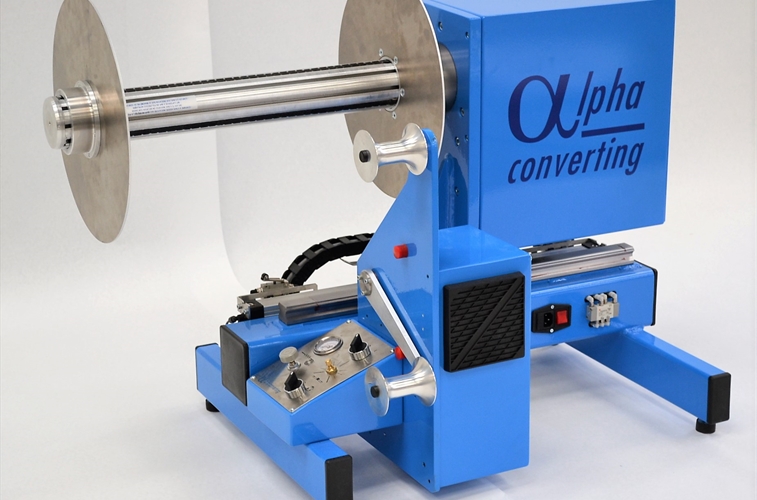

Examples shown:

- Standard pneumatic traversing trim winder with pnematic coreless chuck.

- Pneumatic traversing trim winder with pull roll constant tension drive section for nonstop manufacture of flooring products.

Standard Features

- Pneumatic traversing

- Cantilevered winding shaft

- Closed loop speed control

- Traverse winding

- Variable traversing rate

- Quality engineered and manufactured in UK

Optional

- Pull roll for constant pull during roll change

- Coreless winding to minimise waste

- Winding of 2 trims on one winder

- Low tack roll coverings for exposed adhesives

- Path rolls

- Shaftless chucks

- Side flanges

- ATEX rating

- Special configuration to match existing production equipment

Typical Specification

| ALPHATRIM TWM-P Trim Winder | ||

| Trim width | 5 to 65 mm | 0.2 to 2.5 inches |

| Web thickness | 10µm to 1 mm | 0.4 to 40 mils |

| Package diameter | 350 mm | 14 inches |

| Package width | 350 mm | 14 inches |

| Core diameter | 76 mm | 3 inches |

| Speed | 150 m/min | 500 ft/min |

| Maximum Speed | 250 m/min | 800 ft/min |

Typical Materials

| Film - OPP, PET, PE, PVC | Medical | Carpet |

| Non-woven | Packaging films | Floorings |