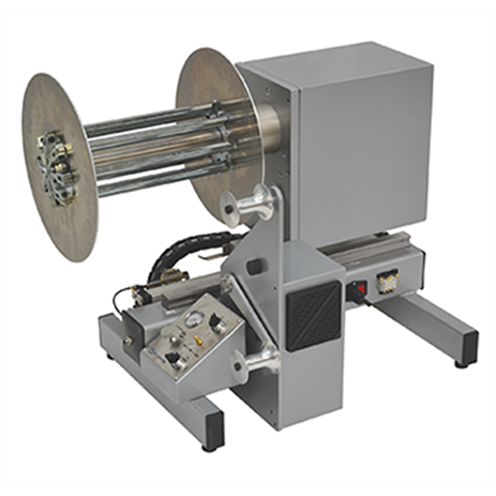

TWM Trim Winders

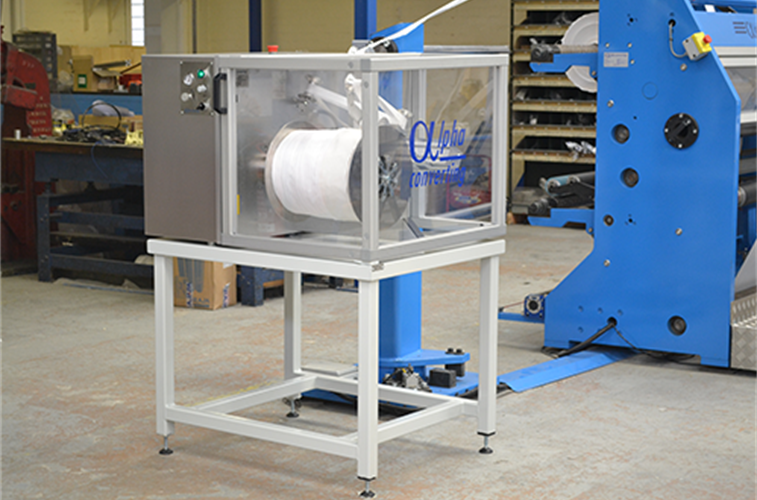

ALPHATRIM TWM trim winders are designed to provide compact, high speed, efficient removal of trim from converting lines without the noise, dust and high cost of installation associated with many vacuum systems.

The ALPHATRIM TWM is a stand-alone unit which does not need any integration with the host slitter. Each trim winder is driven by its own variable speed motor running under closed loop tension control from a precision pneumatic dancer, which automatically tracks the speed of the host slitter.

Rewinding is either on a cardboard core or coreless to provide even easier recycling opportunities.

With speeds up to 600mpm and operator adjustable tension and oscillation control the ALPHATRIM TWM provides a very simple and efficient trim winding solution.

Standard Features

- Fully electronic controlled traversing

- Trapezoidal (Pineapple) winding profile

- Cantilevered winding shaft

- Closed loop speed control

- Traverse winding

- Variable traversing rate

- Quality engineered and manufactured in UK

Optional

- Winding of 2 trims on one winder

- Rewind cheek plates (flanges) for slippery films

- Pull roll for constant pull during roll change

- Coreless winding to minimise waste

- Low tack roll coverings for exposed adhesives

Typical Specification

| ALPHATRIM TWM Trim Winder | ||

| Trim width | 5 to 65 mm | 0.2 to 2.5 inches |

| Web thickness | 10µm to 1 mm | 0.4 to 40 mils |

| Package diameter | 350 mm | 14 inches |

| Package width | 350 mm | 14 inches |

| Core diameter | 76 mm | 3 inches |

| Maximum Speed | 300 - 600 m/min | 900 - 2,000 ft/min |

Typical Materials

| Film - OPP, PET, PE, PVC | Medical | Foam tapes |

| Non-woven | Packaging films | Laminates |