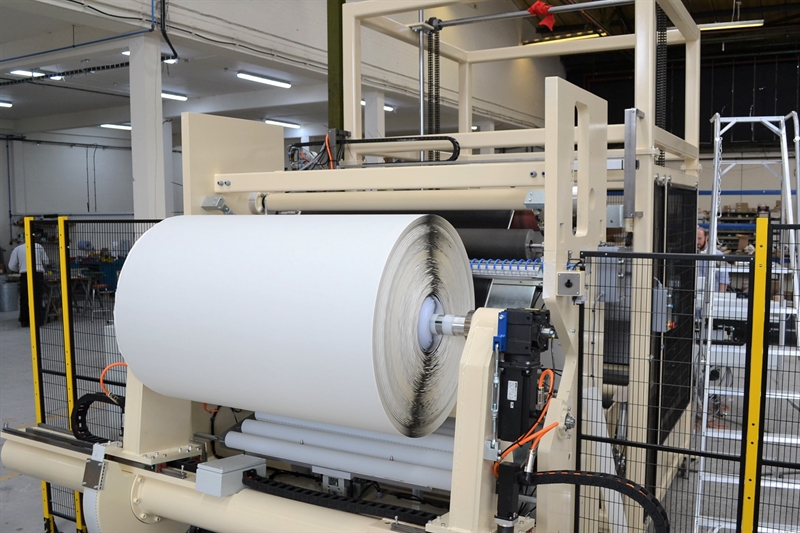

Automatic Rewinders

ALPHAMATIC rewinders fully automate the winding process for a wide range of product types.

Read moreThe single position winder provides cycle times below that of many turret rewinders and the full cycle is completely independent of any operator involvement. Each automatic winder is custom engineered to provide optimum benefit to the production process.

ALPHAMATIC machines can operate independently with their own unwind (off-line), or in line with a customer's continuous process.

Examples shown:

- Automatic narrow roll winder for food wrap films. Manual core loading and roll unloading.

- Automated roll bagging with product identification label printing and label application.

Standard Features

- Fully automatic roll transfer

- Centre winding

- Automatic core loading

- Precise tension control with torque controlled rewinding

- PLC control with touch screen interface and comprehensive recipe and maintenance systems

- Closed loop unwind tension control

- Quality engineered and manufactured in UK

Optional

- Coreless rewinding

- Roll closure by label

- Taped start

- Slitting

- Automatic knife setting system

- Core and roll labelling

- Discharge to conveyor

- Auto bagging

- Off-line or In-line operation with existing customer production lines

- Wrapping systems to customer specification

- Web accumulator for non stop operation

- Turnkey supply, including packing, transport and start-up

- Label printing systems for cores, rolls and bags or boxes

- Rewind unloading systems

Typical Specification

| ALPHAMATIC | ||

| Web width | 250 to 2,000 mm | 10 to 80 inches |

| Rewind diameter | 50 to 400 mm | 2 to 16 inches |

| Rewind core diameter | 76 mm | 3 inches |

| Unwind diameter | To 1,800 mm | 70 inches |

| Material thickness | 25 to 500 µm | 1 to 20 mils |

| Line speed (maximum) | 300 m/min | 1,000 ft/min |

| Operator interface | Colour touch screen | |

Typical Materials

| Coated Paper | Floorings | Non-wovens |

| Film | Textiles | Label stock |