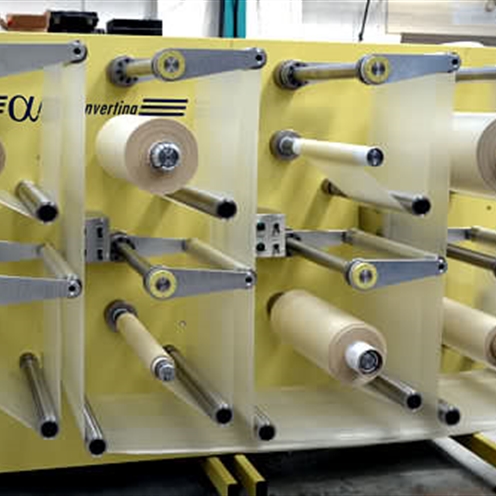

Salvage Rewinders and Inspection

ALPHASAVE salvage rewinders and inspection machines are available for a wide range of materials and roll sizes.

ALPHASAVE winders are supplied with manual web inspection, automatic web inspection or none depending on the purpose. Standard salvage (doctor) machines allow you to recover badly wound rolls or to remove faults identified in the roll. Inspection machines are supplied with bidirectional winding, whilst combining machines are optimised for loading of small in-feed rolls for quick consolidation into one large roll.

Standard Features

- Shaftless chucking

- Precise tension with closed loop tension control

- Edge guiding (web guide)

- Length counting

- Touch screen operator interface

- Quality engineered and manufactured in UK

Optional

- 100% web inspection

- Light box

- Rewind splicing table

- Loading/unloading from the floor

- Precision pneumatic brake or AC driven unwind

- Label/impression counting

- Edge trimming

- Shafted or shaftless winding station.

- Multiple tension zones

- Centre guided web

- Clean room installation

- Layon roll

- Peel off roll (unwind)

Typical Specification

| ALPHASAVE Salvage Rewinder | ||

| Web width | 25 to 2,000 mm | 1 to 78 inches |

| Roll diameter | 150 to 1200 mm | 6 to 48 inches |

| Core diameter | 76 or 152 mm | 3 or 6 inches |

| Edge guide | ± 75 mm | ± 3 inches |

| Material thickness | 10 µm to 5 mm | 0.4 mils to 0.2 inches |

| Line speed (maximum) | 20 to 1000 m/min | 60 to 3,000 ft/min |

Typical Materials

| Film - OPP, PET, PE, PVC | Laminates | Paper |

| Non-woven | Textiles | Label stock |

| Medical | Packaging | Newsprint |

.JPG)