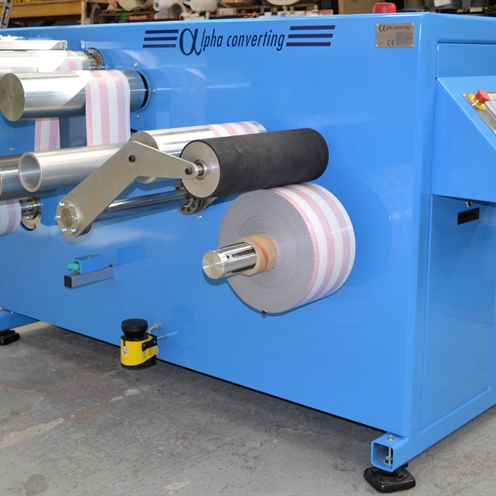

Custom Built Unwind Rewinders

ALPHAREEL winders can be configured for any application requiring the unwinding or rewinding of a web.

Alpha Converting's engineering expertise in a wide range of material types and processes ensures the best winder for your application.

ALPHAREEL winders are of heavy duty construction for long life.

Examples:

- Multi channel unwind stand for narrow web with closed loop tension control and web guiding on every winder. Quick release chucks for rapid roll change.

- Turret cantilevered unwind with flying splice web transfer for narrow web application.

Standard Features

- Custom design to suit manufacturing line

- Precision closed loop tension control

- Edge guiding (web guide)

- Quality engineered and manufactured in UK

Optional

- Shafted or shaftless

- Precision pneumatic brake or AC drive

- Automated roll handling

- Line guiding

- Multiple rolls

- Non stop operation

- Touch screen operator interface

- Almost anything!

Typical Specification

| ALPHAREEL Custom Built Winder | ||

| Web width | 1 to 3,500 mm | 0.04 to 140 inches |

| Roll diameter | 200 or 2,500 mm | 8 or 100 inches |

| Core diameter | To suit | To suit |

| Edge guide | Up to ±250 mm | Up to ±10 inches |

| Material thickness | 10 µm to 5 mm | 0.4 mils to 0.2 inches |

| Line speed (maximum) | 2000 m/min | 1,000 ft/min |

Typical Materials

| Film - OPP, PET, PE, PVC | Laminates | Paper |

| Non-woven | Textiles | Board |

| Medical | Copper | Aluminium |

| Packaging | Self adhesive | Label stock |

.JPG)