Shaftless Unwind Rewinders

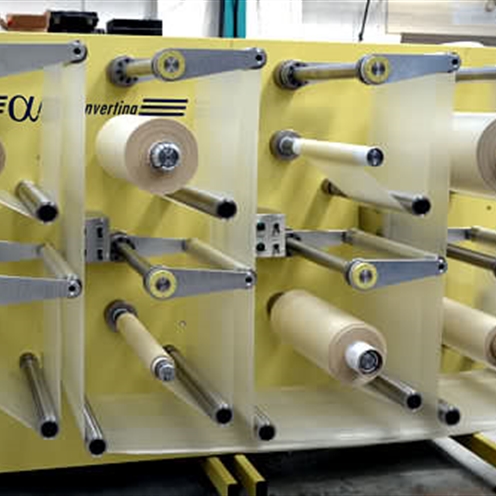

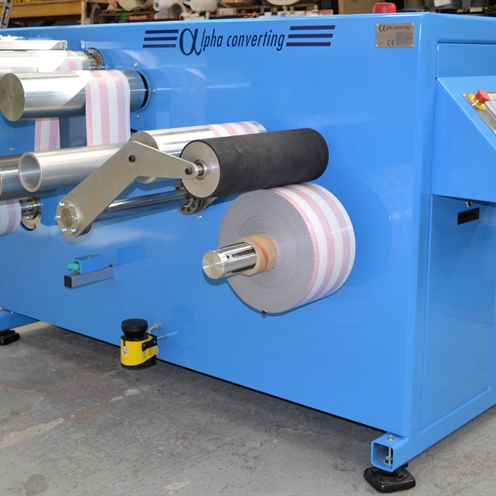

ALPHAREEL shaftless winders unwind and rewind a wide range of products without the need for shaft handling.

Shaftless chucks are selected to suit the customer cores and may be air inflated, torque activated or mechanically expanding through end pressure.

ALPHAREEL shaftless winders are of heavy duty construction for long life.

Examples:

- Twin unwind stand for board, sheeting, or corrugating line. Featuring floor loading trolley with hydraulic pick-up, and closed loop unwind tension control with pneumatic brake and load cells.

- Special shaftless unwind stand for air bags with multiple tension zones and automatic edge or centre web guide modes. Close loop dancer tension control with motor drive for both unwind roll and web feed to process line.

Standard Features

- Shaftless chucking

- Precise tension with closed loop tension control

- Edge guiding (web guide)

- System integration with production line

- Quality engineered and manufactured in UK

Optional

- Pick up from the floor or roll cart

- Precision pneumatic brake or AC drive

- Automated roll handling

- Line guiding

- No hydraulics

- Twin roll stand

- Non stop operation

- Web threader

- Touch screen operator interface

- Multiple tension zones

- Centre guided web

- Clean room installation

- Layon roll (rewind only)

- Peel off roll (unwind only)

Typical Specification

| ALPHAREEL Shaftless | ||

| Web width | 1,000 to 1,800 mm | 72 inches |

| Roll diameter | 600 or 1,800 mm | 24 or 72 inches |

| Core diameter | 76 or 152 mm | 3 or 6 inches |

| Edge guide | ± 75 mm | ± 3 inches |

| Material thickness | 10 µm to 5 mm | 0.4 mils to 0.2 inches |

| Line speed (maximum) | 1000 m/min | 3,000 ft/min |

Typical Materials

| Film - OPP, PET, PE, PVC | Laminates | Paper |

| Non-woven | Textiles | Board |

| Medical | Copper | Aluminium |

| Packaging | Self adhesive | Label stock |

.JPG)