Individual Arm Slitter Rewinders

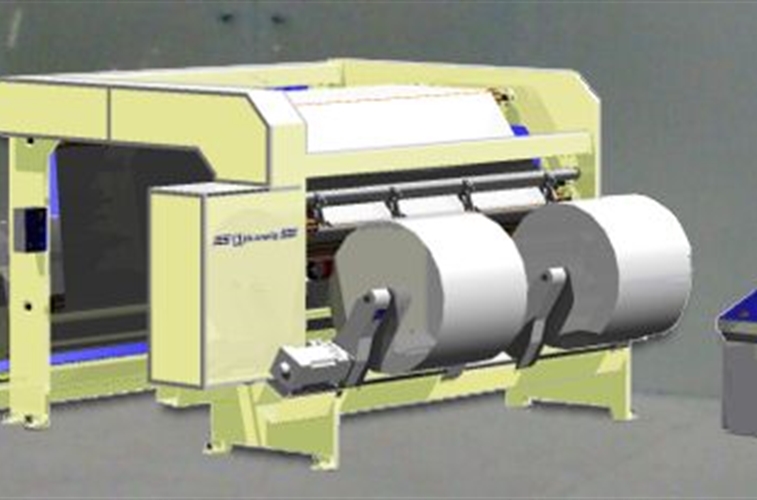

The ALPHAWIND individual arm centre and centre surface winders provide the ultimate in winding of sensitive and thin films.

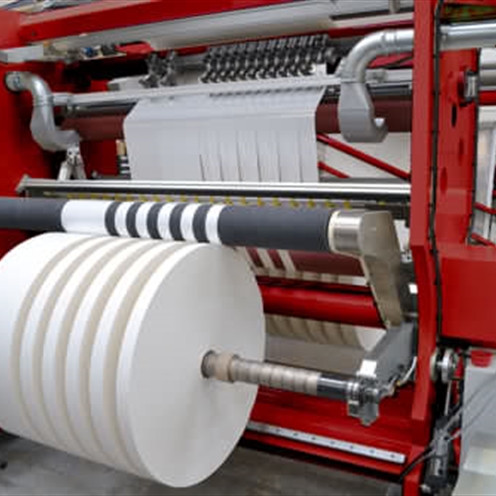

Each roll is driven by its own servo motor for precise tension control with independent contact control for controlling roll density. The shaftless winding technology provides high speed unloading of the rolls either manually or, for larger rolls, directly onto roll carts. All models can be supplied with automatic knife positioning and powered or automatic arm positioning to improve productivity. The touch screen operator interface has simple recipe systems for multiple material types and slitting parameters.

Examples shown:

- ALPHAWIND C300 with integrated unwind for clean room operation. Shaftless unwind with roll lift picks roll directly from floor or roll cart.

- Precision winding head with constant geometry ultralow friction layon assembly for sensitive laminates.

- ALPHAWIND 1000 heavy duty centre winder with overhead web path for coated papers and films.

Standard Features

- Individual motor drive for precise tension on every roll

- Individual pneumatic contact layon rolls

- Servo driven rewind tracking

- Quick roll change with powered or manual chucking

- PLC control with touch screen interface and comprehensive recipe and maintenance systems

- Closed loop unwind tension control

- Quality engineered and manufactured in UK

Optional

- Automatic knife setting system

- Automatic arm positioning

- Trim removal

- Automated roll unloading

- Automatic core loading

- Powered roll stripping

- Unloading trolley

- Turnkey supply, including packing, transport and start-up

- Higher line speeds - up to 1,000 m/min (3,000 ft/min)

- Razor, shear or score slitting

- Rewind unloading systems

- Multiple rewind banks for slit widths down to 50mm

- Stainless construction for clean room or food grade installations

- Unwind tension control through AC drive system or precision air brake

Typical Specification

| ALPHAWIND | ||

| Web width | 1,000 to 3,000 mm | 40 to 120 inches |

| Rewind diameter | 300 or 1,000 mm | 12 or 40 inches |

| Minimum rewind width | 150 mm | 6 inches |

| Rewind core diameter | 76/152 mm | 3/6 inches |

| Unwind diameter | 800 to 1,500 mm | 30 to 60 inches |

| Material thickness | 10 to 500 µm | 0.4 to 10 mils |

| Line speed (maximum) | 600 m/min | 2,000 ft/min |

| Operator interface | Colour touch screen | |

Typical Materials

| Film - OPP, PET, PE, PVC | Laminates | Paper |

| Non-woven | Textiles | Label stock |