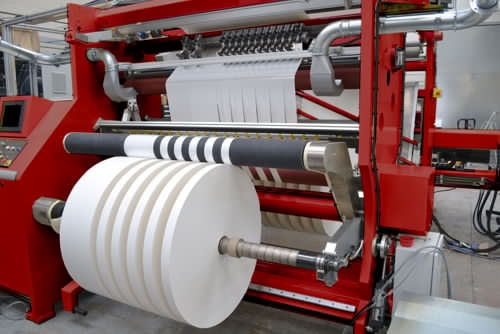

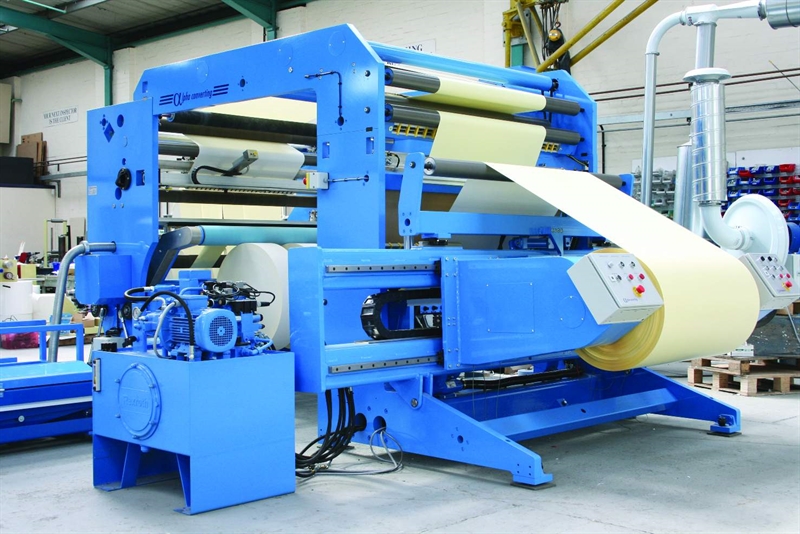

Duplex Slitter Rewinders – heavy duty

The ALPHATWIN HR duplex slitter rewinder for large diameter rewinding with both shafts set at low level for fast and safe unloading, typically used for labelstock or papers.

Read moreHeavy duty rewind shafts with optional centre supports. Driven layon rolls add tension to the centre wind tension for excellent winding of larger diameters. The overhead web path keeps the web clean and visible and leaves space below for handling systems to unload the larger diameter rolls. The ALPHATWIN HR is normally supplied with unload trolleys with integrated scissor lifts to quickly move finished rewind rolls to the side of the machine. The open layout is optimised with fully integrated automatic knife setting and laser core loading for fast job changes.

Standard Features

- Cantilevered winding shafts with swing away support for quick roll change

- Precise tension control with spacer-less differential rewinding shafts or lock core winding

- Driven lay on assemblies

- Large diameter rewind capability

- Powered roll stripping with unload trolleys

- PLC control with touch screen interface and comprehensive recipe and maintenance systems

- Closed loop unwind tension control

- Shear or Razor slitting

- Quality engineered and manufactured in UK

Optional

- Automatic knife setting system

- Crush slitting

- Vacuum Trim removal

- Laser core positioning

Typical Specification

| ALPHATWIN HR | ||

| Web width | 1,000 to 2,000 mm | 40 to 80 inches |

| Rewind diameter | 1,000 mm | 40 inches |

| Minimum rewind width | 50 mm | 2 inches |

| Rewind core diameter | 76 mm | 3 inches |

| Unwind diameter | 1,500 mm | 60 inches |

| Material thickness | 20 to 500 µm | 0.8 to 20 mils |

| Line speed (maximum) | 600 m/min | 2,000 ft/min |

| Operator interface | 10" colour touch screen | |